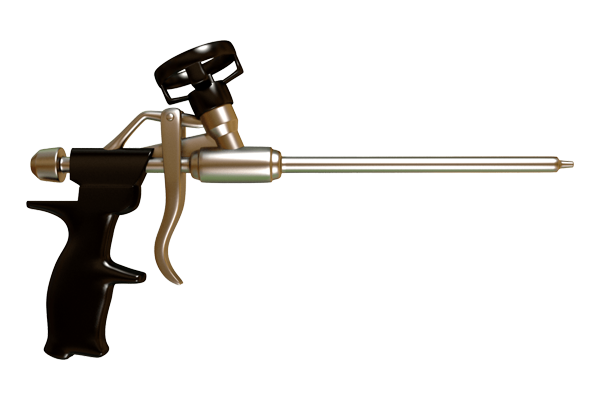

PURATOOL 4110

KEY SPECIFICATIONS

PURATOOL 4110 is a devise to disburse Foam out of cans in a professional manner to have proper control over speed and flow of foam.

- 1K PU dosing device for the professional

- Teflon-coated adapter

- Robust metal housing

- Stretchable foil tape especially for the INNER window joint connection

- Stretchable, airtight film-fleece combination

- Air tight at ≤ 0.1 m³ / (h ∙ m ∙ (daPa) 2/3)

- Diffusion-inhibiting sd value approx. 55 m

- Suitable for RAL-compliant window installation

- Takes due to elasticity targeted component movements

- Both sides can be plastered over and painted over

- Self-adhesive strip with foil cover for gluing on the window frame

- Universal for new construction and renovation

- Color red for visual control

- Economical, versatile, effective and durable

- Dosed foaming of 1K PU foam cans with threaded ring

- For filling joints and connections during window and door installation with PU foam cans

- Versatile use in the construction sector with different PU foam qualities and applications

- For general use of aerosol cans with threaded ring

| FEATURE | TECHNICAL VALUES | TEST CONDITIONS |

| Material for housing | metal | |

| Material for handle | plastic | |

| threaded adapter | Non-stick coating | |

| Total length | Approximately 300 mm | |

| Length of nozzle tube | Approximately 160 mm | |

| mass | Approximately 450 gr | |

| packaging | Single box / 40 pieces in transport carton |

| MATERIAL | FITNESS |

| aluminum | recommended |

| concrete | recommended |

| chrome | recommended |

| tile | recommended |

| fiberglass | recommended |

| plaster | recommended |

| plasterboard | recommended |

| Glass | recommended |

| Wood | recommended |

| ceramics | recommended |

| laminate | recommended |

| metal | recommended |

| polymers | recommended |

| porcelain | recommended |

| PVC | recommended |

| plywood | recommended |

| stone | recommended |

| brick | recommended |

| zinc | recommended |

This table is for guidance only and does not constitute a binding statement. In practice self-tests are to be carried out in advance. Further information can be obtained via our application technology.

- Shake PU foam can approximately 20 times in the longitudinal direction

- Hold the foam can and screw the dispensing gun onto the can thread valve

- Adjust the metering screw and depress the trigger lever with care

- Check first foam strand and do not use (possibly oil / detergent residues in the dosing device)

- Foam can with valve down

- Fill the joint from bottom to top to approx. 80% as the foam expands and fills the joint completely

- When stopping foaming and for can storage, screw metering screw to metering gun.

- Before can change:

- Hold the can with the valve up and spray the dispensing gun empty.

- Unscrew empty can and screw dispensing gun to full can.

- To seal the dispensing gun always leave a can (also empty) screwed onto the dispensing gun.

- Fresh foam can be removed with PU cleaner. Hardened foam only mechanically.

- The PU foam is not UV-stable, therefore it should be coated with suitable means in a timely manner, plastered or covered with UV-proof.

- Intended for commercial and industrial use!

Store in dry, unopened original packaging (<60% RAH) and protected against dust. Protect against mechanical damage.

Only for commercial users. Observe technical data sheet! Dispose according to local regulations.

All information is based on our current technical knowledge and experience. However, since conditions and methods of using and using our products are beyond our control, we recommend that you test the product prior to final use. The information in this technical data sheet and any explanations in connection with this leaflet are not to be considered as a guarantee. Proposals for use do not constitute an assurance of suitability for the recommended purpose. We reserve the right to adapt the product to technical progress and to new developments. If the application for which our products are used is subject to regulatory approval, the user is responsible for obtaining these approvals.